Wastewater Treatment

If imitation is the sincerest form of flattery, then Mother Nature must be pleased. Nature’s system of wastewater treatment through rivers, lakes, and streams is straightforward: heavy particles settle to the bottom, while lighter particles float to the top where microorganisms feed and further break down these particles. These microorganisms grow larger and eventually settle at the bottom. Water is absorbed by the riverbed and filtered through layers of rock into the underground water supply. While this process is excellent, it is not efficient enough for our large population. What nature accomplishes in up to a year, modern science can achieve in less than a working day. Our contemporary treatment plants can process wastewater through the tertiary treatment phase in less than eight hours, utilizing the basic principles of Mother Nature.

SPOTLIGHT

Wastewater Treatment Projects

Manteca, California

City of Manteca – Industrial Pipeline Treatment Facilities

- (1) 20HP aerator

- (2) 7.5HP influent pumps

- PLC-based controls/HMI interface

- Instrumentation

Burlingame, California

City of Burlingame – Mitten Road Pump Station

Manteca, California

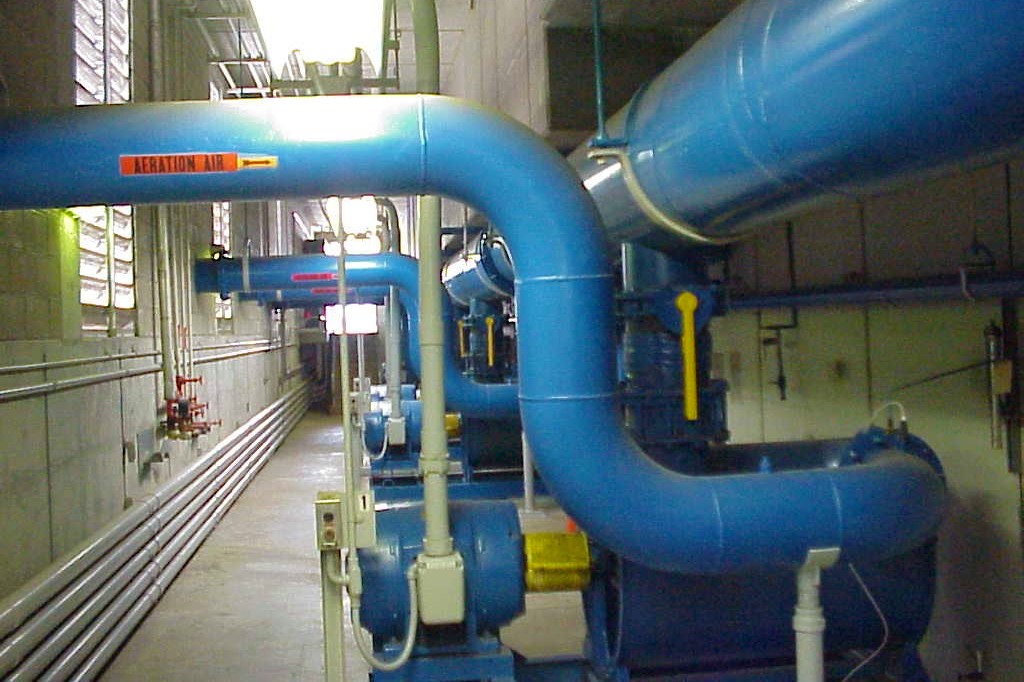

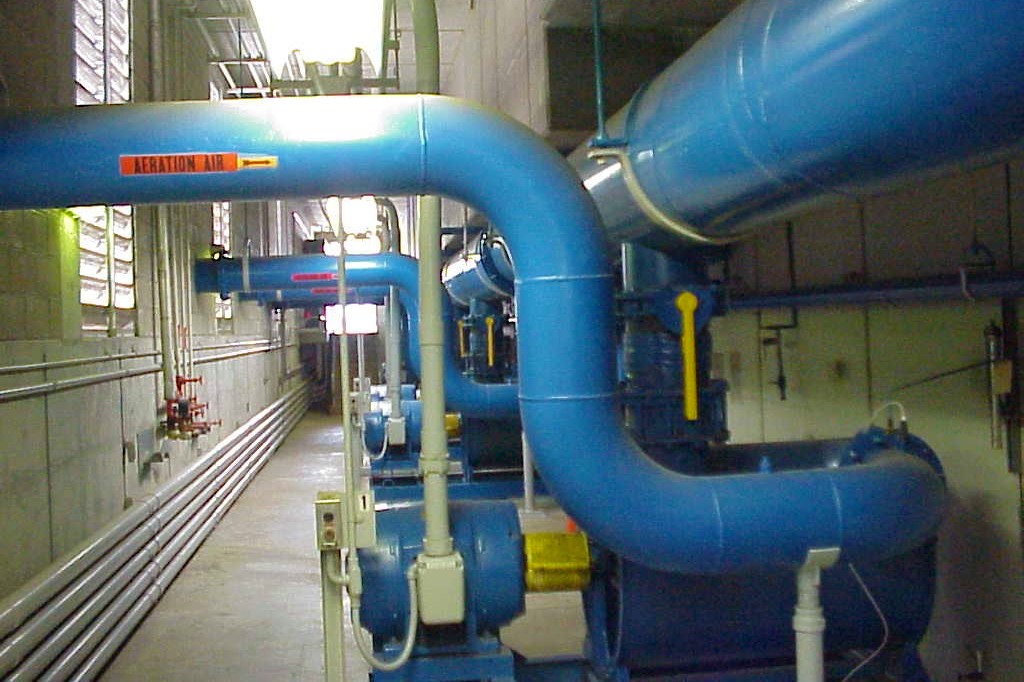

City of Manteca Wastewater Treatment Plant

- Distributed PLC-based controls (Modicon Quantum & Momentum) and instrumentation for new and existing plant facilities

- SCADA/HMI system (Intellution iFix) with Ethernet over fiber LAN

- Influent pump station (1200HP), headworks, and biofilters

- Primary treatment facilities

- Aeration basins with combined blower capacity of 1650HP

- UV disinfection facility

- Anaerobic digester and control building with co-generation facilities

- Clarifier and RAS/WAS facilities and centrifuge sludge de-watering facilities

- Irrigation and effluent pumping

- 17kV medium voltage loop service distribution system

- (7) 2000kVA padmount transformers

- (5) 1500kW emergency generators with paralleling capability over fiber optic network & 17kV emergency tie

Camp Pendleton, California

United States Marine Corps Sewage Treatment Plant #2

This project was a key initiative by the military to upgrade from World War II-era sewer treatment technology to modern solutions. It has resulted in a more efficient and thorough system while also contributing to the protection of the fragile Santa Margarita River basin. EETS engineers were responsible for designing the following components:

- 1.0MGD wastewater treatment plant

- 17kV primary service

- 4.50kW digester gas co-generation unit

Manteca

Manteca Wastewater Quality Control Facility

- The design of a new 17kV service and a 17kV underground loop distribution system to all new and existing plant process areas, featuring medium-voltage duct banks, vaults, and padmount transformers for normal and emergency services.

- The design of a distributed emergency generation system with step-up transformers and an interconnection to the 17kV loop system.

- PLC-based controls and instrumentation for new and existing plant facilities.

- SCADA/HMI systems.

- UV disinfection systems.

- An anaerobic digester and control building with 450kW co-generation facilities.

- RAS/WAS facilities.

- Centrifuge sludge dewatering facilities.

- Primary sedimentation and aeration basins.

- Irrigation and effluent pump stations.

Tuolumne Sanitary

Tuolumne Sanitary District Wastewater Treatment Plant

- Modifications to the Head Works, including a flowmeter and either a traveling screen or grinder.

- Aeration facilities, including blowers or alternative systems.

- A new control building featuring a shop, garage, storage, laboratory, control room, and offices/conference room.

- Demolition of existing electrical service and control facilities and integration of their functions into new electrical equipment.

- A new main switchboard and related facilities.

- Three tail water recovery pump stations and controls.

- A PLC-based control system at the plant and at the remote reservoir.

- A PLC-based HMI system at the WTP Control Room.

- A radio communication system between the plant and reservoir.

- Coordination with the Architect and other disciplines in the preparation of the Pre-Design Report.

- Provision of a Radio Path Survey for the implementation of the SCADA Communication System.